Open questions

This subdirectory outlines what we view as some of the key unsolved problems in molten salt reactor development – these are areas where new technologies and/or new companies are needed to fill crucial gaps.

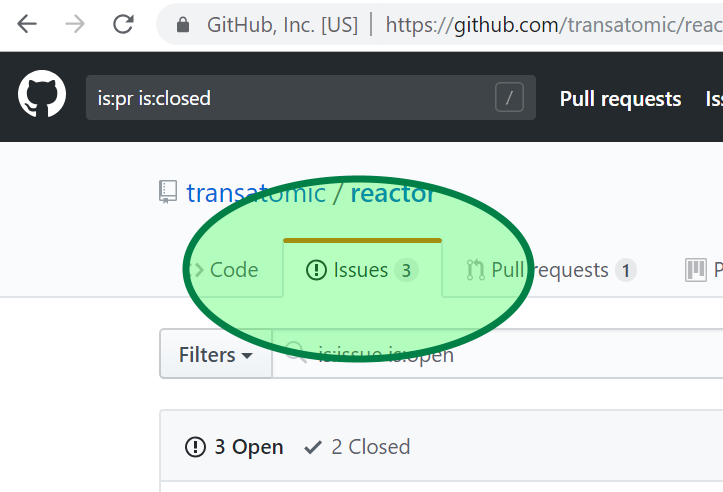

We’d love to get your feedback on additional issues you’ve identified as well. You can add new ones via the github repo’s issue tracker (tab at the top of the repo page,) and we’ll integrate them here.

MSR Safeguards and Materials Control

Liquid fuel is inherently more difficult to monitor and safeguard than solid fuel. At the most basic level, monitoring solid fuel relies on counting fuel assemblies – this is not possible with liquid fuel. In an MSR, it is necessary to keep careful track of both

- the volume of the fuel salt and

- its isotopic composition

to ensure that materials are not being diverted from the site. The situation is further complicated by the fact that the fuel salt is not necessarily homogenous within the reactor. Several new technologies could be developed to help address this problem, including the following:

- Flow meters and other monitoring devices capable of withstanding the high temperatures, radiation damage, and corrosive environment of an MSR.

- Methods of evaluating off-gas composition (e.g. using mass spec) as a cross-check for reactor isotopic composition.

- Methods to directly (in situ) monitor fuel salt composition in the reactor.

- Secure communications protocols for outside verification of these measurements.